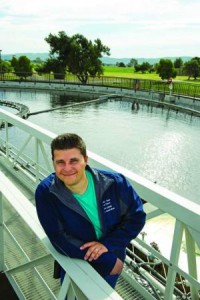

Starting Out as an Immigrant Was Challenging. This Lab Tech Cleared the Hurdles and Found Success. Joga Chizer came from India and built himself a career as an award-winning lab technician and mentor to his colleagues. Joga had no kind of background for the clean-water industry. As an immigrant, he wanted a job. He found an opportunity in an interesting field, and he made a career of it. He’s now the senior lab technician for the Fairfield-Suisun Sewer District in Fairfield, California, and the 2020-21 Laboratory Person of the Year, designated by the California Water Environment Association.

Clearing hurdles

It wasn’t easy getting his start in the profession. Chizer came to the United States from India in 1990 at age 25 with a master’s degree in political science. His only science courses were in high school; he immigrated because he married an American woman. He landed in San Francisco and needed a job because his degree wasn’t useful there.

“I applied to 10 or 12 places for a job, and at that time people were picky,” he recalls. “They were, ‘Oh, you’re new. You don’t have experience.’” A call came early one morning offering an interview as a dishwasher. He thought it was at a restaurant and asked for the address.

“I got there, and it was an analytical lab called Pace,” he says. That was in Novato, California. “They said, ‘We need a dishwasher who can follow the procedures and make sure all the glassware is clean.’” The lead technician, a Russian immigrant, offered to train him when not busy with his primary job, he says.

So Chizer started learning how to measure pH, conductivity and TSS, and do other basic tests. As his ability and eagerness became clear, he learned how to analyze for cyanide, phosphate and other substances. After two years, a chemist who had left the company told him about an opportunity with his organization, Caltest Analytical Lab in Napa, a startup lab with only seven team members where everyone was doing multiple jobs.

“They said, ‘Can you do this? Can you do this?’ I said, ‘You tell me what to do, I’ll do everything.’” And he did: dishwashing, sample pickup, lab work and cleaning and sample preparation for the organic department, such as gas chromatography mass spectrometry analysis. “I said, ‘Train me, I will do it.’ So I was there for 11 years.”

One Caltest client he tested samples for was the Fairfield-Suisun District. At the time, the district’s treatment plant was run by a contractor. Chizer went to work for the contractor in 2003. In 2007, the district took over operation of the lab and hired Chizer. In 2008, the district took over operation of the entire plant.

Recycling water

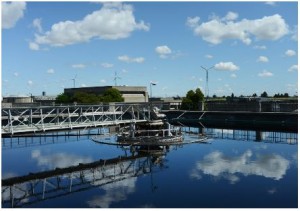

Inside the plant, after mechanical bar screens and primary clarifiers, the wastewater is sprayed over plastic media in oxidation towers. Intermediate clarifiers settle solids after the oxidation towers while the wastewater flows on to an activated sludge process. Secondary clarifiers are followed by a set of aeration basins for denitrification, and then sand and anthracite filters and UV disinfection (WEDECO).

Some of the effluent is sent into a slough that eventually enters the chain of bays and channels leading to San Francisco Bay. The rest is reused. A sod farm immediately west of the plant receives some of the recycled water, and the city of Fairfield uses it for irrigation.

About five years ago the district outsourced its biosolids handling to Lystek, which takes cake from the gravity belt thickeners and a screw press (FKC Co.) and produces fertilizer for area farms. The average daily flow is 14 to 15 mgd, Chizer says, but in the event of heavy rains and flows, the plant has the capacity to store and process up to 50 mgd. Several large ponds hold influent during heavy rains or when the plant might be temporarily shut down.

Sampling on wheels

Chizer’s job isn’t as complicated as at Caltest because the Fairfield-Suisun lab isn’t set up for complex testing. For example, samples from nearby Travis Air Force Base are sent to Caltest because the samples require expensive, specialized equipment.

The plant itself covers 600 acres. “Every operator has a golf cart,” Chizer says. “Maintenance has golf carts, and the lab has golf carts. We use big jugs — 10-liter, 15-liter, 20-liter jugs. To bring them to the lab you need a cart. And there’s a time limit. You have to be in the lab within 15 minutes of sampling.”

Technicians arrange their routes to meet that limit. It typically takes three trips to collect all the samples. The lab is in the process of meeting the standards formulated by The NELAC Institute (TNI) and adopted by the state of California. “It’s like attention to detail. It’s very interesting,” Chizer says. “The bar is high.” The team has been working on compliance for more than two years, and it will be two more years until they must conform to the standard.

Chizer’s days don’t vary much: “The only thing is, it’s a standing job. You cannot sit. So I compare my lab with the kitchen at home. Even for data entry, I always do it standing up.”

Questioning the status quo

The nomination for his CWEA award was a stabilizing influence during a time of transition. During the pandemic he had a new supervisor, and the question was how to make the lab function under social distancing and other health regulations needed to contain the virus.

Managers considered outsourcing some lab work; Chizer told them that would affect operations. No commercial lab can turn samples around as fast as in-house technicians, so operators couldn’t react as quickly to changes in the plant.

They discussed how to have Chizer and Raymona Shirmard, the other technician, in the same space. “I said, ‘I will have the lab four days all by myself, and she will have the lab three days all by herself, and we will communicate through email and all the other ways.’ And that schedule was pretty much permanently set. We worked one day a week together, Wednesday. We had a one-hour meeting and stayed apart, six, seven, eight feet with masks.”

As he dug into TNI standards, Chizer began questioning the rationale for some of the lab’s work. “I said, ‘When did we have any violation for TSS, ammonia, BOD?’ They figured 900 data points, no violation. I said, ‘Then why are we doing this all the time?’” At district managers’ request, the state agreed to a reduced frequency of once a week for those tests.

Helping others advance

Another reason for his CWEA award was his mentoring of colleagues. “When I studied for the Lab IV exam, I put all the material together from whatever source,” he says. “That could be going to conferences, going to lab meetings or dinner meetings. And whoever I find who’s an expert, I always talk to.

“It took me a year plus to pass this exam. Then I knew everything about the exam: what they’re asking for, how they ask, how they make trick questions.” He saved all the information he had collected and then he began helping others with the exam. He taught five people at the plant, people who had nothing to do with the lab, and they all passed the Grade IV lab exam.

A previous supervisor who had moved to another county needed a Grade IV license to keep her job. Chizer had two three-hour training sessions with her; she also passed. He also guides people who express interest in a wastewater career and is regularly involved in plant tours.

“I tell them do this, take this class. Are you in high school? Are you good at math? Do you want to be an operator? Take this class and look for a job as an operator in training. If someone gets into this industry, no matter what you do, there’s a lot of opportunity to grow.”

Personal time

In his spare time, Chizer watches sports: “You ask me anything about sports, and I’ll have the answer right in front of me.” He doesn’t watch sports popular in India, like cricket or soccer.

“I belonged to a very poor family,” he says. “No matter how cold or hot it was, I never had shoes. I had flip-flops. When they broke, we repaired them. Over here it’s a different story.” In his new country, baseball and football are his favorites, along with basketball.

Chizer agreed that America is a land of opportunity: “When life takes a turn, you have no idea what is going to happen. So you wait for those moments. It’s all in your control. You can say no to anybody. You can say yes to anybody. That’s how much power you have.”

Flexibility includes not letting yourself be controlled. Suppose you are cut off in traffic, he says. “They make you mad, right? You don’t even know the person. You’ve already given control to the person you don’t even know, and you’re upset. Go on with your life.”

Published by David Steinkraus in the July 2022 issue of Treatment Plant Operator topmag.com

Ben Carver loves the wastewater industry. As an operator/maintenance technician 5 at the Fairfield-Suisun Sewer District in California, Carver is focused on expanding his knowledge while helping fellow operators develop the skills they need to advance their careers.

Ben Carver loves the wastewater industry. As an operator/maintenance technician 5 at the Fairfield-Suisun Sewer District in California, Carver is focused on expanding his knowledge while helping fellow operators develop the skills they need to advance their careers. Carver’s interest in wastewater began when he was 15 and trying to figure out what to do with his life. A family friend who worked for the City of Fairfield Water Department described life at the water plant, leading Carver to look at classes at Solano Community College. The first one he found happened to be about wastewater, so he enrolled and decided to make it his career.

Carver’s interest in wastewater began when he was 15 and trying to figure out what to do with his life. A family friend who worked for the City of Fairfield Water Department described life at the water plant, leading Carver to look at classes at Solano Community College. The first one he found happened to be about wastewater, so he enrolled and decided to make it his career.