In many ways, operators have one of the best jobs imaginable. Ask yourself these questions and see how an operator would answer them:

Do you want a job that challenges you?

An operator is one who is always learning, doing something different, researching ideas, solving problems and protecting life.

Do you want to become an investigator?

Operators must learn how to apply investigating techniques to discover the culprit of equipment malfunctions or plant process inefficiencies.

Do you enjoy fixing things that are broken?

All things eventually break down, so an operator gets to work with an immense variety of equipment and tools in order to fix, replace, rebuild or invent things.

Do you want to work outside, or at a desk, in a laboratory or a mechanical shop? Do you want to work with your hands or with you mind?

As an operator, you will do all of it. Your job is to operate a wastewater treatment plant and all that it entails. Each day you may do something different. You will taste what it is like to be a biologist, a chemist, an engineer, a mechanic, a regulator, a landscaper, an analyst, and much more.

Operators are not just workers; we are active participants in a venture that protects public health, and preserves natural resources. We clean, we check, we fix, we investigate and we make decision to ensure the plant and its process is making the best quality of water it can. We have the opportunity to be always moving, always growing, and always learning. It is a dirty job that is both physically and mentally demanding, yet rewarding. There is always a laugh to be had and something new to do. It is not just a job, it’s a career that one falls in love with in spite of oneself.

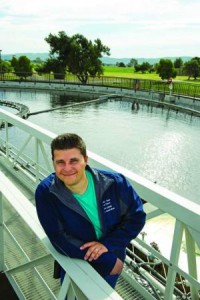

Ben Carver loves the wastewater industry. As an operator/maintenance technician 5 at the Fairfield-Suisun Sewer District in California, Carver is focused on expanding his knowledge while helping fellow operators develop the skills they need to advance their careers.

Ben Carver loves the wastewater industry. As an operator/maintenance technician 5 at the Fairfield-Suisun Sewer District in California, Carver is focused on expanding his knowledge while helping fellow operators develop the skills they need to advance their careers. Carver’s interest in wastewater began when he was 15 and trying to figure out what to do with his life. A family friend who worked for the City of Fairfield Water Department described life at the water plant, leading Carver to look at classes at Solano Community College. The first one he found happened to be about wastewater, so he enrolled and decided to make it his career.

Carver’s interest in wastewater began when he was 15 and trying to figure out what to do with his life. A family friend who worked for the City of Fairfield Water Department described life at the water plant, leading Carver to look at classes at Solano Community College. The first one he found happened to be about wastewater, so he enrolled and decided to make it his career.